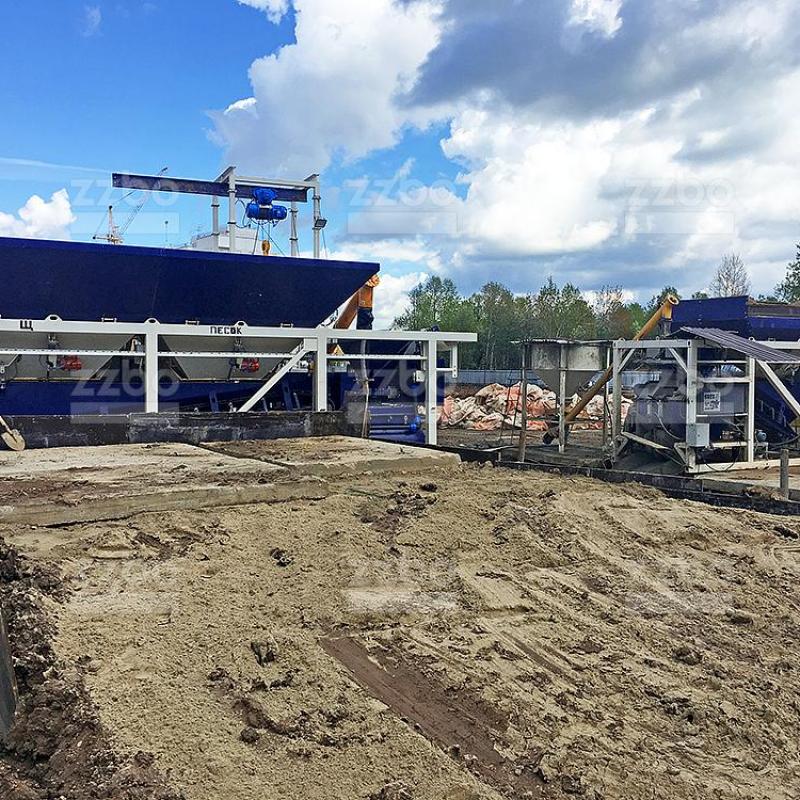

Mobile Concrete Batching Plant "MOBIL-45" at wholesale

Negotiated Price

Mobile concrete plant MOBIL-45, with a productivity of up to 45 cubic meters of concrete per hour of work. Transportation in one 40 ton container or Euro truck. The plant is delivered fully ready for operation, does not require adjustment, adjustment and preparation of the foundation. It is installed in an open area, on any dense surface without preparation, or in any room with a ceiling height of at least 5 meters. Commissioning is the connection of a voltage of 380 volts and the supply of water. Takes no more than two hours! The principle of operation in automatic mode: Inert (sand, sifting, crushed stone, etc.), which will be used in the production of concrete / mortar, are distributed over the compartments of the inert hopper by name. The number of bins is 2 pcs. In the same way, cement, silo, water and additives in the supply tanks are distributed according to the class. After choosing a specific recipe for concrete preparation, the required volume (m3) is entered. After that, the installation proceeds to production. Inert ones are weighed individually according to the weight given in the recipe. Weighing occurs as a result of opening the shutters of the inert hopper and pouring them onto the weight conveyor. Dosageless inert materials are fed into a concrete mixer by means of a weight conveyor. Cement, water and various additives are supplied to the appropriate dispensers, where they are weighed depending on the recipe specified in the automated system. After dosing, all components of the concrete / mortar in turn, through the metering dampers, are fed into the concrete mixer. The mixture of all components is mixed in a twin-shaft concrete mixer for a certain time and in the form of concrete / mortar is fed through the drain valve of the mixer. Two-shaft concrete mixer BP-2G-750. Volume is 750 liters. Forced-type concrete mixer, twin-shaft. With horizontal shafts. The total number of blades is 14. The drive power of the mixer is 11 kW. Rotation of shafts with a frequency of 36 revolutions per minute. Spokes type "Fist", adjustment along the shaft. 16 mm thick blades from wear-resistant high-strength cast iron 16 mm thick, adjustable. Allows you to adjust the clearance. Armor is also made of wear-resistant cast iron with a thickness of 10 mm, interchangeable, bolted. The warranty period to wear is at least 2 years or 40,000 cubic meters of concrete. Unloading is done through Camozzi air lock. 0.5 cubic meters of concrete is produced in one cycle. The cycle lasts about 40 seconds. Thus, 1 cube of concrete is produced in one and a half minutes of operation of the MOBIL-45 installation. Dosing hopper DK-24. It has a large capacity of 24 cubes of inert materials. These are two bins with a volume of 12 cubic meters. meters. Large loading width of bins - 3 meters. The conveyor is equipped with a chevron belt and a lined drum. Weight conveyor, suspended suspension sensors CAS (South Korea). Inaccuracy of a dosage of 1%. Conveyor drive power 11 kW. The bunkers are equipped with two camozzi pneumatic valves and two Oli shakers. Dosing unit BD-30. It consists of three components: cement dispenser, water dispenser and chemical additive dispenser. The 300 kg cement dispenser is equipped with a Camozzi pneumatic damper and an Oli vibrator shaker. A weight batcher is located on three Cas load cells (South Korea) A 150 liter water batcher, on three high-precision Cas load cells (South Korea) A stainless steel chemistry dispenser. The chemical and water dispensers are equipped with a pneumatic valve for draining Camozzi fluid. Compressed air system compressor ABAC B 4900B Consists of the Italian piston compressor Abac B 5900B / 200 CT 5.5 and the Camozzi pneumatic system. Productivity is 653 liters a minute, with a power of 4 kW. Pressure 11 atm. Receiver 200 liters. The compressor is already integrated in the frame and is protected from the environment and dust. PAM control panel. Work on the principle of pressing a single button, select the concrete brand - the amount of concrete and press the start of the cycle! Controller and touch graphic control panel OMRON (Japan) Productivity 45 m3 / hour for ready-mixed concrete (during continuous operation, with recipes with 2 aggregate components, 1 binder component (maximum weight 300 kg per 1 m3 of concrete), with normal flow, 5% humidity of sand, the ratio of water / cement equal to 0.5, with 30 seconds of stirring and a positive ambient temperature.The delivery of the finished mixture is a tub.

Russia

Russia