Flour Disinfecting and Bleaching Machine at wholesale

Negotiated Price

• Ozone is one of the most potent disindectant material, 3125 times more than chlorine.

• Rapid and potent oxidating effect

• A continous antimicrobial effect via destroying the cell wall of the microorganisms

• A very effective deodorisma effect A very effective colour change, whitening in the flour

• Natural and enviroment - friendly

• There is no residue after application

• A very potent chemical purification via removal of the chemical residues on the raw & finished product

• Anticancerogen effect by removal of the radicals

• Low energy consumption !!!

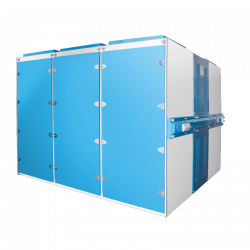

Technical Features

» A dry Air coming from Compressor

» Air Volume : 100 It / min

» Pressure : 1.5 Bar

» Total Power ; 4 kW

» Cooling : Continuous Oil Cooling System

» Volume of cooling Oil Chamber : 53 L Transformer oil

» Motor Power the Cooling Pump : 0,75 KW

» Inner Chassis : Stainless Steel

» Outer Chassis : St37/S235JR/SAE1015

» Capacity ( Flour) :1.750 - 2000 kg / h

» Possibility of Installation During Running

» Flease contact us about capacities of other applications

Application in the Wheat Flour Miils

» Ozonation of the End Product during Horizontal Conveying Process just before Storage and Packing

» Lower Ash Rate due to Purification of the Product from Heavy Mineral Particles

» A very Potent Whitening Effect, Bleaching of the Flour Particles Increase in the Extraction Rate

» A Continious Hygienic Effect within Storage Systems ( Silos, bins etc) Which in turn save Fumigation

» Adjusted Distance Between Ozone Molecules and the Product

» Inhibition of the Larvas and Microorganisms in the Wheat

» Possibility of Increase in Capacity Desired by Use of Multiple Reactors

» Applicable under Various Room Temperatures

Turkey

Turkey