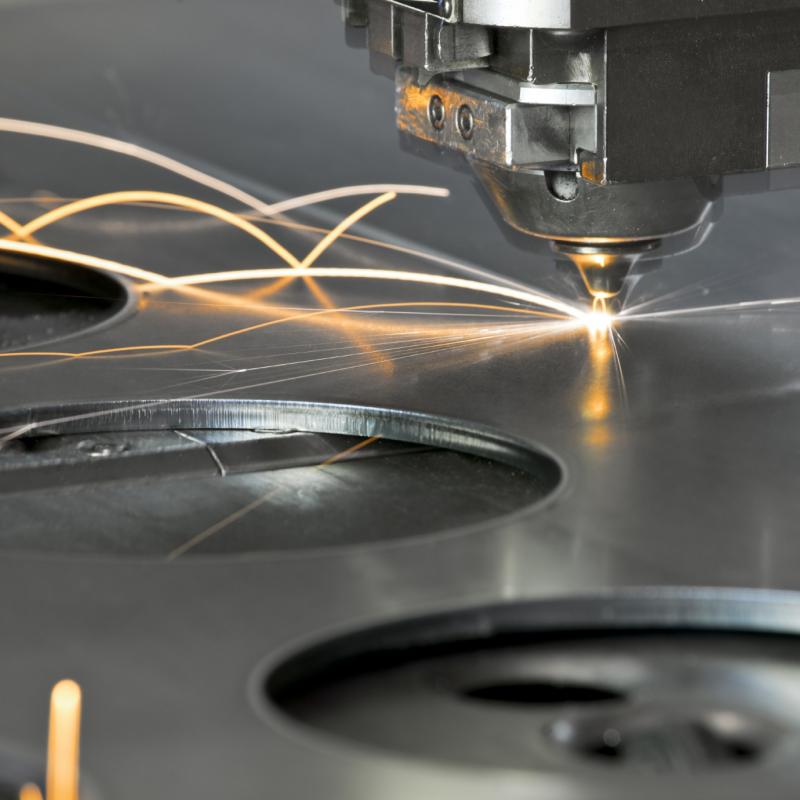

Water Jet Cutting

Negotiated Price

Advantages of water jet cutting:

- Lack of thermal effects at the cutting points

- Ability to process a wide range of materials

- No further processing of the cut is required

- The ability to create products of any most complex shape

- High quality processing of material with a thickness of 0.5 to 50 mm

- No break in the structure when cutting composites

Scope of application:

1.Construction and design (production of exterior and interior products, figured parts from natural and artificial stone)

2.Outdoor advertising (production of volumetric letters, protruding facades, signboards, plates, pointers)

3.Furniture production (production of decorative elements and fixtures)

4.Cutting high precision parts for automated systems, machines and machine tools.

5.Glass cutting

6.Equipment manufacturing (gears, castings, etc.)

7.Aircraft and aerospace

8.Rubber industry

9.Manufacturing of components for cars.

Kazakhstan

Kazakhstan